|

|

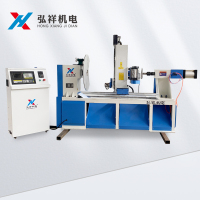

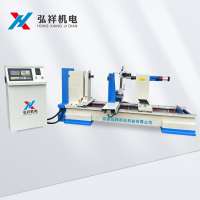

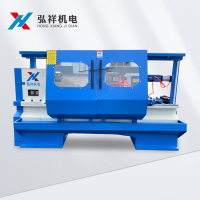

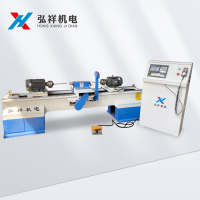

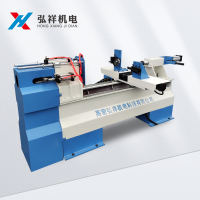

Three axis six knife CNC woodworking lathe

Collect

PRODUCT PARAMETERS

PRODUCT ADVANTAGES Advantages of equipment 1. The CNC woodworking lathe is equipped with three axes and six knives. Six knives are processed at the same time. The design of front and rear knives can reduce the runout of workpiece processing and improve the processing accuracy. 2. According to different processing requirements, the turning proportion can be adjusted freely to meet the processing requirements of high-precision workpieces. 3. The machine tool adopts scientific mechanical design, made of cast iron, wear-resistant, durable and stable. Drawing operation advantages 1. It is easy to draw, supports a variety of drawing formats and drawing software, and is convenient for people without drawing foundation to operate. 2. The drawing is read and written in USB flash disk to avoid input errors by untrained personnel. 3. Realize one person drawing input and multi person on-site operation, and realize division of labor and cooperation between management and operation. Operating system advantages 1. Automatic map recognition can read and write quickly and can be processed without complex programming. 2. The professional CNC operating system can be upgraded and updated with USB flash disk to realize remote writing and local operation. 3. Professional high-precision CNC operating system, simple operation, learning without professional knowledge and short semester; The system can effectively control the machining accuracy and improve the product consistency. 4. The pause memory function can be used for testing and processing of workpieces, and can also be used for resuming processing in case of abnormal shutdown such as power failure. Advantages of equipment accessories 1. equipped with high-quality frequency converter to support the adjustment of processing speed during processing operation. 2. The high-precision and high torque feed motor can meet the large turning quantity and improve the machining efficiency. 3. Variable frequency speed regulation, stepless speed change, save electric energy, and adjust the speed in real time according to the size of the workpiece. 4. High performance transmission system to ensure the quality of processed workpieces and the service life of equipment. 5. Air cooled electric control cabinet can effectively reduce the temperature of electrical control cabinet and prolong the service life of various electrical components 6. Spindle overload protection ensures that the equipment operates under normal load and effectively protects important parts such as motor and frequency converter. Optional Accessories ·Optional rotary cutter table · optional four claw self centering chuck · optional electronic brake · optional servo transformer · optional universal adjustable support |